Halifax is tackling its housing crisis with new zoning rules and funding aimed at creating affordable homes for middle-income workers. These changes allow up to four units on small lots without rezoning, fast-tracking approvals and reducing costs. With federal funding and simplified processes, property owners can now build fourplexes, sixplexes, or walk-up apartments profitably while addressing the rental gap for essential workers like nurses and teachers.

Key points:

- New zoning rules: Up to 4 units on most lots, faster permits for projects under 8 units.

- Construction costs: $160,000–$200,000 per unit, depending on energy efficiency and method.

- Rental income: $1,950 to $2,100/month for two-bedroom units.

- Profitable returns: 12–20% annually with efficient designs and fixed-price contracts.

- Building options: Fourplexes, sixplexes, walk-up buildings, and modular construction.

Halifax’s updated policies and funding incentives make workforce housing a feasible and rewarding opportunity for property owners.

Zoning Rules and Site Requirements in HRM

HRM Zoning By-Laws for Multi-Unit Buildings

In Halifax, updated zoning regulations make it easier to move forward with multi-unit developments, provided they meet specific design criteria. In many areas, smaller projects - those under a certain unit count - can skip the lengthy council review process. To ensure compliance, property owners should confirm that their lot meets requirements for height, parking, and lot dimensions by consulting with HRM planning staff.

Water, Sewer, and Stormwater Connections

Before permits are issued, Halifax requires confirmation of adequate water pressure, sewer capacity, and stormwater management. Engaging with Halifax Water early in the planning process is crucial to determine whether the existing infrastructure can support the project or if upgrades are needed. Some municipalities even offer waivers on water and sewer connection fees to encourage the development of workforce housing [1][4].

Site Readiness Checklist

Thoroughly evaluating the site is essential. Key considerations include access for construction vehicles, proper grading, and alignment with the surrounding neighbourhood. Ensure there’s enough street frontage for emergency access and check for any heritage or design guidelines that might require additional approvals. The site's proximity to employment hubs and quality schools can also boost rental appeal. Opting for a location already zoned for multi-unit use and equipped with municipal services can simplify the process and save time [3]. With a compliant lot and solid infrastructure, property owners can move forward with confidence, exploring the best build options for workforce housing.

Build Types That Work on Small Urban Lots

Fourplexes and Sixplexes

Fourplexes and sixplexes are a smart choice for Halifax's narrow urban lots. With Halifax Regional Municipality (HRM) allowing up to four residential units as-of-right, property owners can skip rezoning delays. These buildings fit comfortably on lots as narrow as 25 to 42 feet, thanks to their stacked layouts that optimize space.

Construction costs for these smaller multi-unit buildings in Halifax start at approximately $160,000 per unit when using an integrated design-build approach. Rental income typically ranges from $1,950 to $2,100 per month per unit, offering annual returns between 12% and 20%, depending on factors like land costs and financing.

One way to keep costs down is by using single-stair designs, which eliminate the need for elevators and a second egress route. This approach can cut construction expenses by about 20% compared to dual-staircase buildings. Additionally, double-exposure layouts - where windows face two sides of the building - improve natural cross-ventilation, lowering cooling costs and enhancing tenant comfort.

For those looking to maximise vertical space even further, mid-rise walk-up buildings provide another option.

3-to-5-Storey Walk-Up Buildings

Mid-rise wood-frame buildings are ideal for increasing unit density on small lots. HRM's updated zoning now supports higher densities and reduced parking requirements, making these structures financially feasible even on compact urban sites. For example, a four-storey walk-up can accommodate around eight units on a lot that might otherwise hold fewer residences in a traditional low-rise setup.

These buildings often feature wood-frame construction with sloped roofs, avoiding the need for roof access stairs and keeping costs in check. Staying below the elevator threshold - roughly 18 metres (60 feet) or five storeys - further reduces expenses. Pre-zoned lots with existing municipal services also help property owners achieve favourable Floor Area Ratios.

For developers seeking financing through CMHC's MLI Select program, buildings must be 40% more energy-efficient than the minimum code requirements. While this adds about $200,000 per unit to construction costs, it unlocks advantages like 95% financing and a 50-year amortization period. Common energy-efficient features include triple-pane windows, enhanced insulation, and ductless heat pumps, which not only lower operating costs but also attract higher-quality tenants.

For even faster and more cost-effective construction, modular and factory-built options are becoming increasingly popular.

Modular and Factory-Built Options

Halifax's short building season and rising construction costs make modular construction a practical solution. By shifting most of the work indoors, modular methods cut project timelines from 12–18 months to just six–eight months - saving nearly two months compared to traditional stick-built homes [7]. Faster timelines mean rental income starts sooner.

In 2023, nearly 20% of new modular homes sold for under $300,000, compared to 14.2% of stick-built homes [7]. For multi-unit buildings, modular construction can reduce costs by 10% to 30%, thanks to factory efficiencies, bulk material purchasing, and less waste. The controlled indoor environment also protects materials from weather damage, ensuring high-quality results that often surpass traditional site-built structures.

These modular units adhere to the same provincial building codes as conventional construction, guaranteeing comparable safety and quality. Modules can be stacked to form three- to five-storey buildings, with horizontal connections creating complete floor layouts. This approach allows site preparation and module fabrication to happen simultaneously, shortening the overall project timeline and potentially lowering financing costs. Modular construction works particularly well for standardised designs, like fourplexes and sixplexes, where repetition enhances factory efficiency.

Construction Costs and Rental Income

Per-Unit Construction Costs

In Halifax, the cost of building workforce housing varies widely, largely influenced by the type of construction and the approach taken. For example, integrated design-build projects - where a single team handles both design and construction - can deliver units for around $160,000 each in fourplexes or sixplexes. On the other hand, fragmented construction methods, which involve multiple contractors and more coordination, can increase costs by 30–60% due to inefficiencies.

Breaking down the expenses, hard costs (materials and labour) make up about 37% of total costs, while soft costs (design, permits, and other indirect expenses) account for roughly 24% [9]. Halifax Regional Municipality (HRM) has introduced updated zoning regulations, effective October 3, 2025, to help lower these costs. These changes include waiving on-site parking requirements and removing maximum height restrictions [10].

For projects aiming to meet CMHC MLI Select standards, per-unit costs hover around $200,000. These units are built to exceed minimum energy efficiency standards by about 40%, incorporating upgrades like triple-pane windows, better insulation, and ductless heat pumps. While these enhancements increase upfront costs, they unlock financing perks, such as 95% financing and 50-year amortization, which dramatically improve financing leverage - often reaching ratios of 20:1, compared to the typical 5:1.

An alternative approach, factory-built or modular construction, brings its own advantages. These controlled processes can cut construction timelines significantly, from the usual 12–18 months to just 6–8 months. While the cost savings are sometimes debated, the real benefit lies in the faster project delivery.

Once construction costs are established, the next critical factor is how rental income affects a project's financial feasibility.

Rental Rates for Workforce Housing in HRM

In Halifax, two-bedroom workforce housing units typically rent for $1,950 to $2,100 per month. These units cater to middle-income households earning between 80% and 120% of the Area Median Income (AMI). This group often earns too much to qualify for subsidized housing but still finds luxury rentals out of reach.

One of the main challenges for landlords is the gap between current market rents and the "economic rent" needed to achieve a 10% cash-on-cash return over a decade. This underscores the importance of keeping construction costs manageable and choosing efficient building methods [11]. Properties with premium features - like smart home systems, Energy Star appliances, and in-unit laundry - can justify higher rents and often attract long-term, reliable tenants. Additionally, delivering units fully "rental ready" eliminates delays in rent collection, improving cash flow right from the beginning.

ROI Calculations for Small Multi-Unit Projects

Let’s consider a practical example: a fourplex in Halifax built at $160,000 per unit, totalling $640,000 in construction costs. If each unit rents for $1,950 per month, the property generates around $93,600 in annual gross rental income. To calculate actual returns, you’d subtract operating expenses like property taxes, insurance, maintenance, and allowances for vacancies.

Projects financed through CMHC MLI Select benefit from lower monthly debt payments thanks to extended amortization periods, making them cash-flow positive from the start - even with higher upfront costs. In contrast, conventional financing requires a debt coverage ratio (DCR) of at least 1.20, making cost control essential. Delays or cost overruns in fragmented construction models can severely impact profitability. For example, a 30–60% increase in mid-project costs can derail financial plans, and every month of construction delay can result in approximately $7,800 in lost rental income for a fourplex.

sbb-itb-16b8a48

We Built 4 Rentals, Now They Make $80,000/Year (Full Breakdown)

Construction Delivery Methods Compared

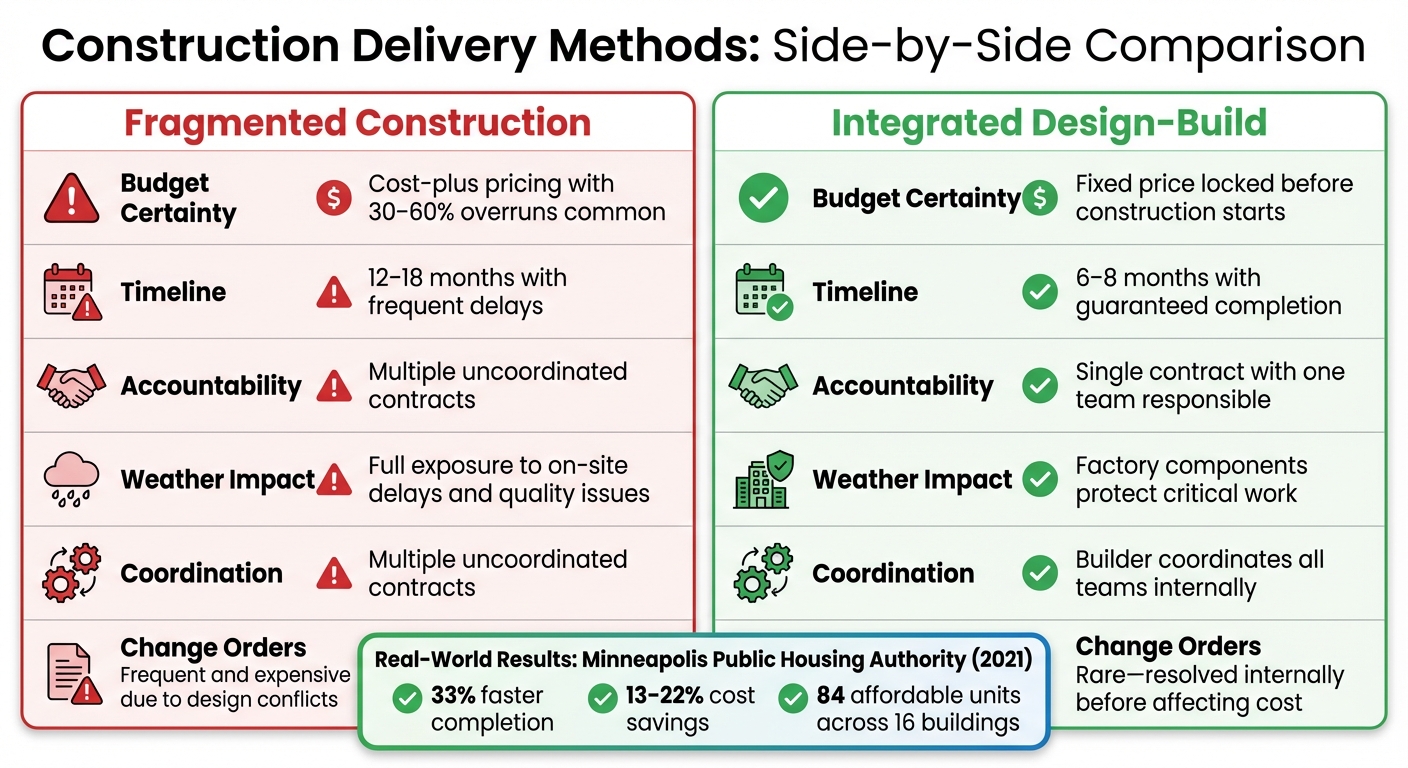

Fragmented vs Integrated Design-Build Construction Methods Comparison

Problems with Fragmented Construction

When property owners hire separate architects, engineers, and contractors, they often end up juggling multiple independent professionals who aren’t fully aligned. Each team works on its own, producing separate drawings and specifications, which frequently lack coordination. This fragmented setup can lead to costly missteps. For instance, a property owner might initially budget $640,000 for a fourplex, only to encounter $192,000 to $384,000 in unexpected costs due to design conflicts and change orders. Without a single point of accountability, resolving these issues becomes a complex and expensive ordeal, leaving the property owner to absorb the added expenses.

Delays in timelines only add to the financial strain. A project that ideally should take 8 months can stretch to 18 months, resulting in lost rental income of approximately $7,800 per month for each incomplete fourplex. These extended delays are often exacerbated by factors like weather, labour shortages, and supply chain disruptions, especially when all construction is done on-site without the advantages of a controlled environment.

An integrated design-build approach offers a solution to these challenges.

How Integrated Design-Build Works

The integrated design-build model addresses the inefficiencies of fragmented construction by uniting planners, architects, engineers, and construction teams under one roof. Companies like Helio Urban Development streamline the process by ensuring all parties collaborate from the very beginning. Unified drawings and schedules are created early on, ensuring every detail is coordinated before construction begins.

This approach offers fixed-price construction at $160,000 per unit, with a 6-month timeline. Property owners benefit from cost certainty, knowing their expenses upfront. Additionally, contracts often include penalties - such as $1,000 per day for delays - providing extra assurance. By integrating the process, builders can also use factory-built components strategically, reducing weather-related risks and speeding up timelines by 30% to 50% compared to traditional methods [6].

For those pursuing CMHC MLI Select financing, this approach simplifies the process further. Integrated teams handle everything from energy modelling to CMHC applications, delivering units at $200,000 each while managing the additional documentation required. With a single point of accountability, the entire project - from planning to completion - is handled efficiently and cohesively.

Delivery Method Comparison

The table below highlights key differences between fragmented construction and integrated design-build:

| Factor | Fragmented Construction | Integrated Design-Build |

|---|---|---|

| Budget Certainty | Cost-plus pricing with 30–60% overruns common | Fixed price locked before construction starts |

| Timeline | 12–18 months with frequent delays | 6–8 months with guaranteed completion |

| Accountability | Multiple uncoordinated contracts | Single contract with one team responsible |

| Weather Impact | Full exposure to on-site delays and quality issues | Factory components protect critical work |

| Coordination | Multiple uncoordinated contracts | Builder coordinates all teams internally |

| Change Orders | Frequent and expensive due to design conflicts | Rare - resolved internally before affecting cost |

A real-world example illustrates the advantages of integrated design-build. In 2021, the Minneapolis Public Housing Authority evaluated both methods while planning 84 affordable units across 16 buildings. Their analysis revealed that integrated modular construction was 33% faster and 13% to 22% cheaper than traditional fragmented approaches [8]. The project team - RISE Modular, Frerichs Construction, and DJR - worked collaboratively from the start, enabling tenants to move into the first building by August 2023. This case study highlights how early collaboration and a unified approach can reduce risks and deliver meaningful benefits to property owners.

Conclusion

Property owners in Halifax Regional Municipality (HRM) now have a straightforward path to creating profitable workforce housing on small urban lots. Thanks to federal support through the Housing Accelerator Fund, HRM is set to fast-track 2,600 housing units over the next three years, simplifying approvals and removing obstacles along the way [5][2]. On top of that, Nova Scotia's expanded rent supplement program enhances affordability for tenants, making the financial environment even more appealing for developers [2]. Together, these changes open up exciting opportunities for small-lot housing projects.

To make the most of these conditions, choosing the right type of building is key. Fourplexes, sixplexes, and walk-up buildings are particularly promising, offering strong returns under HRM's updated zoning rules. These rules now allow up to four residential units by default on most lots [2][10]. By fully understanding site requirements - such as water connections, stormwater management, and setbacks - property owners can avoid unexpected costs and delays.

How a project is built also plays a critical role in its success. Opting for integrated design-build methods can provide better reliability and cost control. With fixed-price contracts, single-point accountability, and guaranteed timelines, this approach eliminates the overruns and delays that often plague traditional construction methods.

Strategic funding options further improve project feasibility. For example, Nova Scotia's Affordable Housing Development Program can cover up to 100% of the costs for projects with fewer than 10 units. In some cases, these loans may even convert to grants if affordability conditions are met [2][12]. Additionally, HRM offers fee waivers for non-profit affordable housing projects, saving developers between $10,000 and $40,000 in municipal construction fees. Halifax Water also provides 10-year deferrals on Regional Development Charges for affordable housing initiatives [5][2]. When combined with effective construction strategies and smart building choices, these funding opportunities make it possible for property owners to deliver much-needed workforce housing while achieving strong financial returns.

FAQs

What are the benefits of using an integrated design-build approach for workforce housing projects?

An integrated design-build approach streamlines the construction process by bringing design and construction together under one team. This setup encourages better communication, minimizes delays, and allows for overlapping phases, making workflows more efficient.

By involving builders early in the design stage, this method helps keep costs in check. Budgets are set realistically and are more likely to stay on track. Plus, having a single team responsible for the entire project reduces the chances of miscommunication or unforeseen issues. The result? A smoother delivery process and consistent quality from start to finish.

What are the cost and timeline differences between modular and traditional construction?

Modular construction offers a faster and more cost-effective alternative to traditional building methods, often completing projects 30–50% quicker and at 20–50% lower costs. The key advantage lies in its dual approach: factory fabrication occurs at the same time as on-site preparation, drastically cutting down timelines and labour expenses.

For context, while conventional construction can stretch over 9–12 months or longer, modular projects typically wrap up in just 4–6 months. This efficient process not only saves valuable time but also reduces disruptions, making it particularly suitable for workforce housing on compact urban lots in HRM.

What are the zoning rules for building multi-unit housing in Halifax?

Halifax has made significant strides in accommodating multi-unit housing within ER-3 zones. Recent updates now allow up to 4 units by default on serviced lots and as many as 8 units in the urban core, all without the need for rezoning. These changes are part of an effort to encourage higher-density housing while still offering flexibility for property owners.

The regulations include several key provisions: maximum lot coverage of 60%, restrictions on building height and setbacks, and a limit of 10 bedrooms per unit. These guidelines are designed to strike a balance between increasing urban density and preserving thoughtful community design, ultimately making it more practical to create workforce housing in the Halifax Regional Municipality.

Related Blog Posts

- Small Multi-Unit Development 101: Building Duplexes and Fourplexes in Nova Scotia

- Halifax’s New Zoning Rules Explained: Up to Four Units on a Single Lot (What It Means for Builders)

- Halifax Backyard Suite Plus 4 Units: ER-3 Maximum Development

- Halifax Apartment Builder: Can I Build 4–8 Units on One City Lot?