Frost‑Protected Shallow Foundations in Nova Scotia: Design and Code Notes

Frost-protected shallow foundations (FPSFs) are a cost-effective way to prevent frost damage in Nova Scotia's challenging climate. Instead of deep excavation, FPSFs use insulation to keep soil warm, reducing frost heave risks. This approach works well in the province due to its soil conditions and shorter building season, offering a faster and more efficient alternative to traditional deep foundations.

Key Takeaways:

- How FPSFs Work: Insulation redirects frost away from the foundation, combining vertical and horizontal layers with proper drainage.

- Why Nova Scotia?: The region's soil and climate make FPSFs a practical choice, especially for multi-unit rental properties.

- Construction Process: Shallow excavation, drainage installation, insulation placement, and concrete pouring are key steps.

- Code Compliance: FPSFs meet building codes when properly insulated and drained, even above the frost line.

- Benefits: Reduced excavation, faster timelines, and better energy efficiency.

- Limitations: Requires well-draining soils and careful planning to avoid insulation damage.

FPSFs, when executed with an integrated design-build approach, streamline construction and improve project delivery in Nova Scotia's unique conditions.

Design Principles and Construction Methods

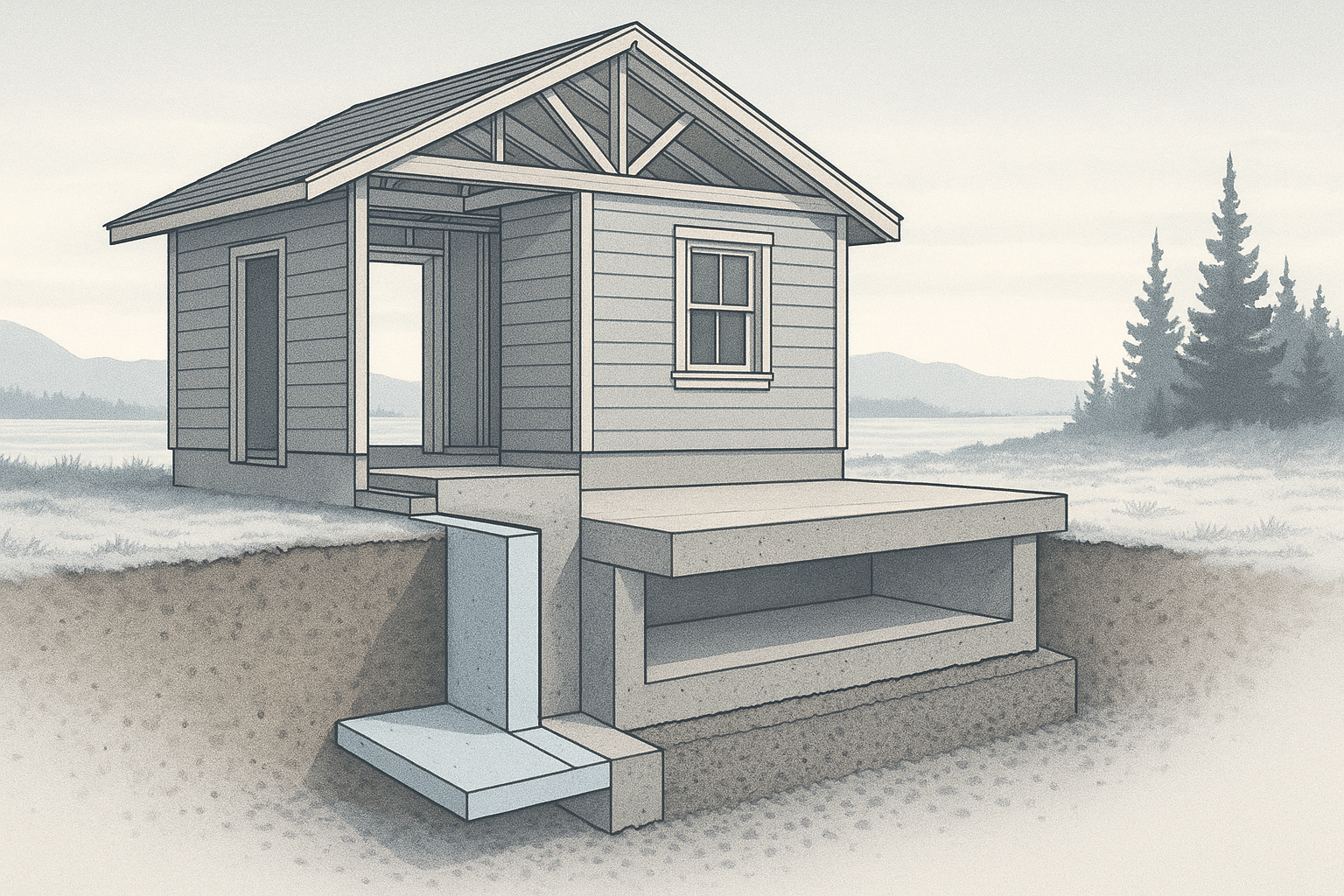

Main Design Features of FPSFs

Frost-protected shallow foundations (FPSFs) rely on three key elements working together: strategic insulation placement, effective drainage, and proper thermal management. Unlike traditional foundations that rely on depth to prevent frost damage, FPSFs use insulation to redirect frost away from the foundation.

Vertical insulation is installed along the outside of the foundation wall, extending from the top of the footing down to where the horizontal insulation begins. Horizontal insulation, in turn, extends outward from the foundation, with its thickness determined by local climate and soil conditions. For Nova Scotia, the insulation must meet specific R-value standards based on the Air-Freezing Index (AFI). Additionally, the building must maintain a monthly mean temperature of at least 18°C (64°F) to ensure the system functions correctly [2].

Proper drainage is equally critical. A minimum 100-millimetre layer of washed gravel or crushed stone is placed beneath the footing to direct water away from the foundation, preventing pooling and freezing. This drainage layer must connect to daylight or an approved stormwater system, particularly in areas with poor natural drainage.

These principles establish the foundation for material selection and construction techniques, which are explored in the next section.

Materials for Nova Scotia Conditions

Rigid foam insulation is a cornerstone of FPSFs, with expanded polystyrene (EPS) and extruded polystyrene (XPS) being the two primary choices. XPS is particularly suited for long-term soil contact due to its resistance to moisture absorption and higher compressive strength, which ensures it maintains its R-value and structural integrity over time. All below-grade insulation must meet ASTM C578 standards to guarantee consistent performance and durability [2].

EPS offers a more economical option while still meeting building codes. However, it tends to absorb more moisture than XPS. With proper installation and adequate drainage, EPS can be a practical choice for projects where cost savings are a priority.

The drainage layer also requires careful material selection. Washed gravel or crushed stone must be clean and well-graded to prevent fine particles from clogging drainage paths. A minimum thickness of 100 millimetres ensures efficient drainage and provides a stable base for the concrete footing.

For insulation exposed above grade, protective coatings such as cement board, parging, or other compatible materials are essential. These coatings shield the insulation from UV damage and physical wear, which is especially important in Nova Scotia’s challenging weather conditions. Without protection, foam insulation can deteriorate quickly, reducing its effectiveness [2].

Integrated systems like Legalett's GEO-Slab simplify installation and improve thermal performance, offering a streamlined approach to FPSF construction [1][3].

Step-by-Step Construction Process

The construction of FPSFs follows a precise sequence, starting with excavation planning tailored to local soil conditions. Unlike traditional foundations that often require digging to depths of 1.8 metres or more, FPSFs typically need an excavation depth of just 300 to 400 millimetres. This shallower depth reduces the risk of encountering groundwater and minimizes disruption to existing drainage patterns.

Site preparation begins with grading to ensure water is directed away from the building footprint. Excavation must account for the drainage layer, insulation thickness, and concrete dimensions while maintaining level surfaces to support consistent insulation performance.

Next, the drainage layer is installed. Washed gravel or crushed stone is spread and compacted to create a stable, well-draining base. This layer must connect to a positive drainage system, such as daylight or an approved stormwater system. Proper compaction is crucial to prevent settlement that could compromise the insulation or create thermal bridges.

Insulation is then placed according to the design plan. Horizontal insulation is installed first, followed by vertical insulation, which is positioned against either temporary forms or the foundation wall itself.

With the insulation in place, concrete is poured. Care must be taken during this step to avoid displacing the insulation or leaving voids that could affect thermal performance. While standard concrete mixes are suitable, timing is critical to address the challenges of Nova Scotia’s shorter construction season and cold weather.

The final steps involve installing protective coverings over any exposed insulation and backfilling around the foundation. Backfill material should be free-draining and placed in layers to protect the insulation system. Throughout the process, quality control measures ensure that insulation remains properly positioned, drainage systems are functioning as intended, and protective measures are adequate for local conditions. This methodical approach ensures FPSFs deliver the thermal efficiency and durability needed for an effective alternative to traditional deep foundations.

Building Code Compliance in Nova Scotia

National and Provincial Code Requirements

In Nova Scotia, the National Building Code of Canada (NBC) requires foundation footings to extend at least 1.2 metres (4 feet) below ground. This depth ensures the footings stay below the frost level, preventing frost heave and maintaining structural stability[4]. However, there is an exception: frost-protected shallow foundations (FPSFs). These foundations can be placed above the frost line if they are properly insulated. This technique uses the principle of thermal interaction - heat loss from the building warms the surrounding soil, effectively raising the frost depth near the foundation and creating a frost-resistant zone[6].

Nova Scotia has adapted these national guidelines to suit local conditions. The province places particular focus on ensuring effective drainage and precise insulation placement, which are critical for FPSF systems to work as intended.

Temperature and Drainage Standards

For unheated FPSF designs, the code specifies a 150-millimetre (6-inch) drain layer to retain geothermal heat beneath the structure. This layer helps prevent freezing by conserving heat from the ground[6]. Additionally, the site must be graded to create a 10% slope over 3 metres (10 feet) to direct water away from the foundation[5]. Proper drainage is essential to keep the soil dry, as moisture can compromise insulation performance. Building codes also require that insulation be installed above the groundwater table to maintain its thermal efficiency[6].

Benefits and Limitations of FPSFs for Property Owners

FPSFs vs Traditional Foundations

Frost-protected shallow foundations (FPSFs) stand apart from traditional deep foundations by requiring significantly less excavation and formwork. Deep foundations typically demand extensive digging and more complex construction processes, which can drive up costs and extend project timelines. FPSFs, on the other hand, are designed for shallower excavation, which can cut down on earthwork expenses. They also include a continuous layer of insulation that helps improve thermal performance. However, these systems are best suited for locations with well-draining soils. This streamlined approach often results in cost and time savings, making FPSFs an attractive option for certain projects.

Advantages of FPSFs

One of the standout benefits of FPSFs is their ability to reduce excavation and earthwork requirements, particularly in areas where challenging ground conditions can complicate construction.

The simplified construction process can speed up project timelines, which is especially valuable in regions like Nova Scotia, where the construction season tends to be short. Faster completion also means quicker access to rental income for property owners.

Another key advantage is improved energy efficiency. The continuous insulation in FPSF designs helps reduce thermal bridging, which stabilizes indoor temperatures and can lower heating costs over the long term.

Additionally, many FPSF systems come with built-in drainage features that direct water away from the foundation. By managing moisture more effectively, these systems can help prevent problems like basement humidity, contributing to a healthier environment for ground-level spaces.

Limitations and Considerations

While FPSFs come with clear benefits, they also require careful planning and evaluation. Soil conditions are a critical factor in their success. These systems work best in well-draining soils, so areas with heavy or clay-rich soils may need additional drainage solutions to ensure proper performance. A geotechnical assessment is essential to evaluate the site’s suitability.

The exterior insulation used in FPSFs can be prone to damage from landscaping equipment, snow removal, or general wear and tear. Protective measures should be put in place to safeguard the insulation during construction and ongoing maintenance.

Another consideration is that FPSFs rely on a coordinated construction approach. The foundation, insulation, and drainage systems must be integrated, which means working with a unified team rather than separate contractors.

Finally, FPSFs are most effective for heated buildings. Structures that are unheated, like seasonal cottages or storage facilities, may not see the same benefits, making this type of foundation less practical for such applications.

sbb-itb-16b8a48

Our Frost Protected Shallow Foundation System

Integrated Delivery and Local Expertise for FPSFs

Efficient project delivery is key to maximizing the thermal and cost advantages of Frost-Protected Shallow Foundations (FPSFs).

Problems with Fragmented Construction

When construction projects are fragmented - spread across multiple contractors handling excavation, foundation work, insulation, and drainage - it often leads to headaches. Cost overruns of 30–60% and delays are common, especially in Nova Scotia, where the short construction season amplifies the impact of any setbacks. On top of that, figuring out who’s responsible when issues like frost heave or drainage failures arise can be a nightmare. This is where an integrated design-build model comes to the rescue.

Benefits of Integrated Design-Build Models

An integrated design-build approach brings everything under one roof. With a single team managing the project, you get fixed pricing, tightly managed schedules, and dependable timelines. This streamlined process not only saves money but also improves the overall quality of construction. Add local expertise into the mix, and the benefits are even stronger.

Helio Urban Development's Expertise in FPSFs

Helio Urban Development stands out as Nova Scotia’s only integrated design-build firm specializing in multi-unit rentals. They offer fixed-price construction at $160,000 per unit, with guaranteed delivery within six months. To back that promise, they include penalties of up to $1,000 per day for delays.

Helio’s edge lies in its understanding of Nova Scotia’s unique conditions. Using local data on the Air-Freezing Index (AFI) and frost depth, the company tailors each FPSF design to meet the region’s demands. These details are crucial for ensuring that insulation specifications match the province's challenging climate and geological conditions [7].

To further enhance performance, Helio uses Advanced Finite Element Modelling to predict heat transfer [1], ensuring the FPSFs perform as intended. Their quality assurance process includes inspections by Professional Engineers at multiple stages and offers property owners the option to select the final inspector. This is topped off with a two-year warranty for added peace of mind. Plus, property owners stay in the loop with daily photo updates and real-time access through a project portal.

Making FPSFs Work for Your Project

Using the design, code, and integration insights discussed earlier, here's how you can effectively implement Frost-Protected Shallow Foundations (FPSFs) for your project.

For property owners in Nova Scotia, FPSFs offer a practical and cost-efficient alternative to traditional deep foundations. They help cut down on excavation expenses, speed up construction timelines, and deliver improved energy performance - all while meeting building code requirements.

However, fragmented construction can be a major pitfall. When different contractors handle separate aspects of the project, miscommunication and coordination issues can lead to costly delays and unclear accountability.

The best way to fully benefit from FPSFs is by opting for an integrated delivery model. When your design, engineering, and construction teams work as one cohesive unit, you gain several advantages: fixed pricing, guaranteed timelines, and a single point of accountability for the entire project.

This integrated approach not only keeps costs predictable but also ensures your project stays on schedule. That means you can start earning rental income sooner instead of dealing with frustrating delays.

To protect your investment, rigorous multi-stage inspections by engineers are conducted throughout the process, and a two-year warranty is included. Plus, with daily updates, you’ll always know exactly how your project is progressing.

FPSFs are especially well-suited to Nova Scotia’s climate when executed correctly. By embracing an integrated approach, you’ll not only ensure the foundation performs as intended but also set your project up for long-term success.

FAQs

What are the cost and time advantages of frost-protected shallow foundations compared to traditional deep foundations?

Frost-protected shallow foundations can save both time and money when compared to traditional deep foundations. In Nova Scotia, where the climate plays a significant role in construction choices, these foundations can lower building costs by roughly $1,500 to $4,000 per unit, depending on the project's scale and site-specific factors.

What makes them so efficient? They require less digging and fewer materials, which means construction moves along faster. By using insulation to guard against frost heave, these foundations offer a sturdy and economical option, particularly for multi-unit residential developments in the area.

Why are frost-protected shallow foundations well-suited for Nova Scotia's soil and climate?

Frost-protected shallow foundations are a smart choice for Nova Scotia, where cold winters and variable soil conditions often lead to frost heave. These systems use insulation to keep ground temperatures stable, preventing freezing beneath the foundation. This approach helps sidestep the expensive repairs that frost movement can cause.

Given Nova Scotia's freeze-thaw cycles, traditional deep foundations can be both costly and labour-intensive. Frost-protected shallow foundations, on the other hand, cut down on excavation needs, meet local building codes, and provide a reliable, budget-friendly solution - especially for multi-unit rental properties.

How can I ensure the insulation in frost-protected shallow foundations (FPSFs) remains effective and undamaged over time?

To ensure insulation in Frost-Protected Shallow Foundations (FPSFs) remains effective and intact, it's crucial to choose sturdy, moisture-resistant materials tailored for colder regions like Nova Scotia. Proper installation plays a big role - make sure insulation boards are firmly secured and shielded from damage during the construction process.

Equally important is maintaining good drainage around the foundation to avoid water build-up, which can weaken the insulation over time. Performing regular inspections can help spot and fix any signs of wear or damage early, keeping the insulation performing well for years to come.