Fire‑Rated Assemblies for Small Multi‑Unit Buildings: Practical Details That Pass

Fire-rated assemblies are essential for fire safety in small multi-unit buildings. They stop flames, smoke, and heat from spreading between units, giving tenants time to escape and reducing property damage. In Nova Scotia, strict building codes require these assemblies to meet specific fire-resistance ratings (30, 45, or 60 minutes) based on a building’s design and use.

Here’s what you need to know:

- Fire-rated assemblies act as barriers in walls, floors, and ceilings to contain fire and smoke.

- Common challenges include navigating complex codes, ensuring proper installation, and passing inspections.

- Inspections focus on airtightness, sealed gaps, and compliance with approved plans.

- Costs average $160,000/unit for standard builds and $200,000/unit for energy-efficient options under CMHC MLI Select financing.

- Delays often result from poor coordination, but integrated design-build methods can reduce timelines to as little as six months.

Planning ahead, using tested materials, and coordinating teams effectively can help you meet code requirements, pass inspections, and protect your investment.

Fire‑Rated Assembly Basics: What You Need to Know

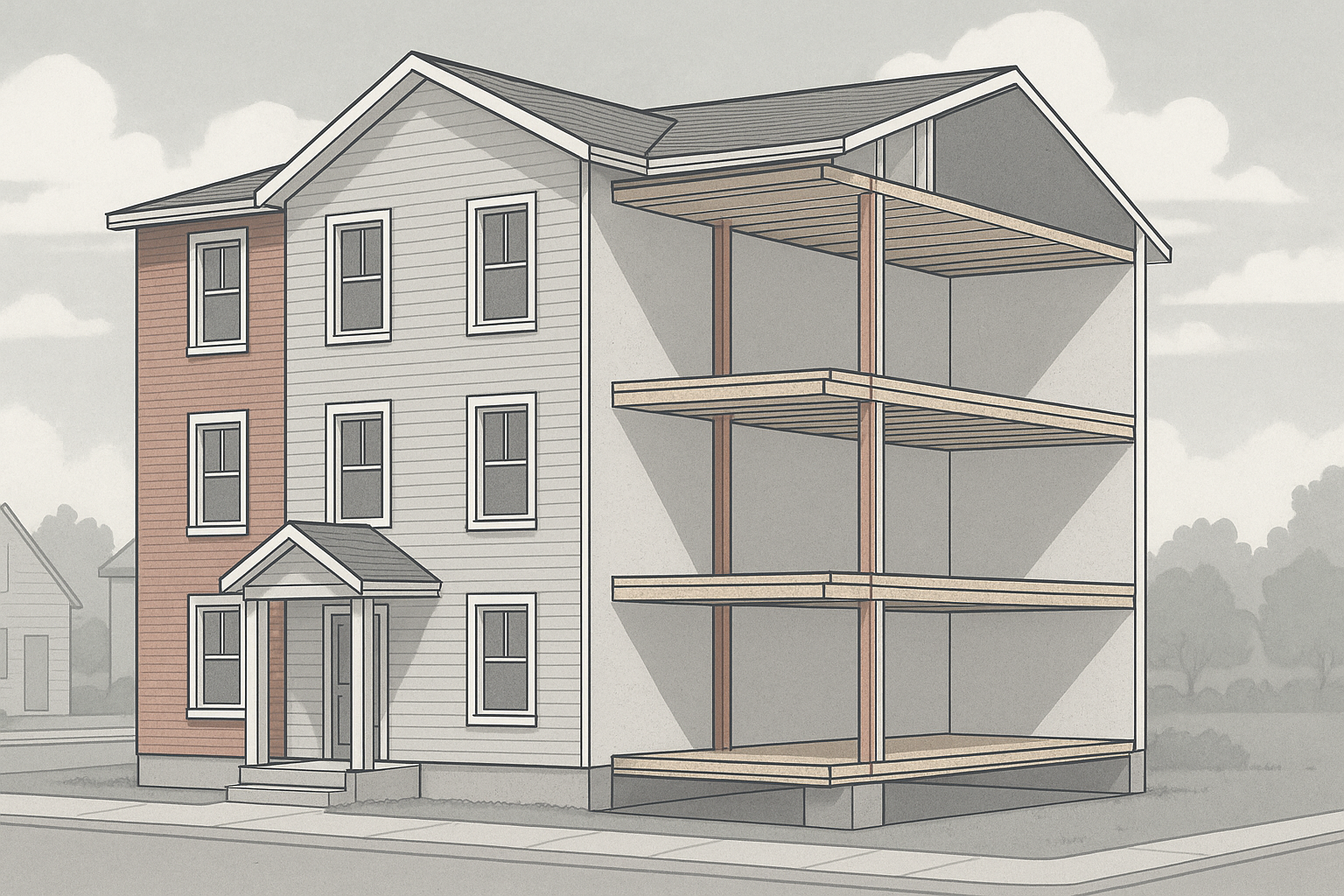

What Fire‑Rated Assemblies Do

Fire‑rated assemblies are a critical part of passive fire protection in multi‑unit buildings. Their main job? To stop fire, smoke, and toxic gases from spreading between different sections of a building.

"Firestopping is the use of fire‑resistant seals to maintain the integrity of passive fire protection systems and block fire and smoke from spreading." - The Home Depot [2]

These assemblies seal up gaps created by essential building features like pipes, electrical conduits, ductwork, and exhaust systems that pass through walls and floors. Without them, these openings could act like highways for flames and smoke, putting lives and property at risk.

Designed to handle extreme heat, fire‑rated assemblies help contain fires to specific areas. This not only protects people but also limits damage to the building.

"In all instances, the goal is to delay the spread of flames, smoke and toxic gasses and give first responders more time to respond." - The Home Depot [2]

For property owners, this means the difference between damage being confined to one unit versus spreading throughout the entire building. These assemblies create fire compartments that can save lives and reduce property loss. To make the most of them, understanding fire‑resistance ratings is key.

Fire‑Resistance Ratings: 30, 45, and 60 Minutes

Fire‑resistance ratings tell you how long an assembly can hold up against fire while maintaining its protective role. In Nova Scotia, small multi‑unit buildings commonly use three ratings: 30 minutes, 45 minutes, and 60 minutes.

These ratings are based on rigorous standardized testing and measure how well an assembly can stop flames, limit heat transfer, and retain its structural integrity. For example, a 30‑minute rating might work for certain residential separations, while 45‑minute or 60‑minute ratings are required for taller or more critical structures. The rating needed depends on factors like building height, construction type, and the specific location of the fire separation.

It’s important to follow the exact specifications of tested assemblies during construction. Simply adding extra layers of drywall won’t boost the rating unless the assembly has been tested and approved in that configuration.

Inspection Requirements and Common Failures

While accurate ratings are essential, inspections ensure that fire‑rated assemblies perform as intended on site. Inspections often focus on whether these assemblies maintain fire separation effectively. Common issues include unprotected openings and doors that lack approved self‑closing and latching mechanisms.

Air leakage is another frequent problem. Traditional fire‑rated gypsum board assemblies may provide excellent fire resistance but often fail to meet airtightness standards outlined in codes like the International Residential Code and International Energy Conservation Code [4]. This not only risks failing inspections but can also hurt the building's energy efficiency.

Unsealed gaps at critical points - such as where firewalls meet exterior walls or extend from the foundation to the roof - can let air flow through, weakening both fire protection and energy performance [4]. To avoid these problems, it’s essential to use gap‑sealing products specifically designed and tested for fire‑rated applications.

"Architects are responsible for documenting code compliance, including fire‑rated wall details. And fire protection engineering is really a specialist area." - John Barrot, President, Banksia [1]

Given the complexity of fire‑rated construction, many property owners find it beneficial to work with builders who specialize in this area. Coordinating multiple trades without expertise can lead to costly mistakes, especially during inspections.

Fire Rated Walls | Residential Applications

Tested Fire‑Rated Assembly Options for Walls, Floors, and Ceilings

Expanding on the fire-resistance basics discussed earlier, here are some practical and tested assembly options designed for walls, floors, and ceilings. These solutions are tailored to meet safety standards while ensuring effective fire protection.

Wall Assembly Options for Fire Separation

For fire separation in walls, builders in Nova Scotia often rely on time-tested assemblies that comply with local code requirements. A common choice is stud wall assemblies, where fire-rated gypsum board is applied to both sides, forming a continuous fire barrier. Double-stud or staggered-stud designs are also popular as they not only reduce thermal bridging but also enhance fire resistance. Another durable option is insulated concrete forms (ICF), which pair noncombustible forms with reinforced concrete for strong fire protection. To ensure the wall assembly performs as intended, follow the gypsum board manufacturer’s installation guidelines and use tested methods to seal penetrations effectively. These wall systems fit seamlessly into broader fire-protection strategies.

Floor and Ceiling Assembly Options

In multi-unit buildings across Nova Scotia, floor and ceiling assemblies must meet strict fire-resistance standards. For retrofits, the minimum requirement is a 30-minute fire-resistance rating [3]. A typical solution involves installing gypsum board ceilings beneath floor joists. In cases where existing assemblies include materials like lath and plaster, gypsum board, or other noncombustible ceiling materials, these are generally accepted as meeting the 30-minute standard [3]. Just like with wall assemblies, it’s crucial to seal all penetrations using fire-rated materials to maintain the fire separation’s integrity. These methods support the comprehensive fire safety approach required for compliance.

Assembly Comparison: Key Considerations

The effectiveness of fire-rated construction depends on maintaining a continuous fire separation throughout the building. This includes eliminating unprotected openings, preventing damage that could compromise the assembly, and ensuring tight joins where different elements meet. These measures not only enhance fire resistance but also improve smoke control [3]. Consistency and attention to detail are essential for achieving reliable fire safety.

sbb-itb-16b8a48

How to Pass Inspections and Avoid Construction Delays

Getting fire-rated assemblies approved starts with careful planning and detailed documentation. Projects that move smoothly through inspections often owe their success to solid groundwork laid before construction even begins.

Planning and Documentation for Code Compliance

Start preparing documentation well in advance of construction. For buildings with specific uses - like licensed residential properties - owners are required to submit sealed building plans to the Fire Marshal before breaking ground[3]. In some cases, the Fire Marshal may also review plans for other types of buildings if requested by a professional engineer or architect[3].

These sealed plans should clearly outline all fire-rated assemblies and include critical details such as boundary surveys, elevation data, and site-specific features. This level of preparation ensures a smoother construction process and helps maintain alignment with code requirements.

How Integrated Design-Build Prevents Problems

Once the planning is complete, using an integrated design-build approach can help avoid common issues. This method brings together architects, engineers, and construction crews into a cohesive team. By coordinating schedules, maintaining consistent quality control, and ensuring direct communication with inspectors, this approach simplifies the approval process and keeps projects on track.

Costs, Timelines, and Guarantees for Fire‑Rated Construction

When it comes to fire‑rated construction, costs, timelines, and contract structures play a crucial role in project planning. These elements not only impact budgets but also influence the efficiency and overall success of the build. Let’s break down the specifics of these factors.

Fire‑Rated Construction Costs in Nova Scotia

In Nova Scotia, constructing fire‑rated multi‑unit buildings typically costs about $160,000 per unit for standard builds that adhere to all building code requirements. This includes the cost of fire‑rated assemblies and the skilled labour needed to install them. Aside from meeting regulatory standards, this investment enhances tenant safety and preserves property value.

For those looking to maximise financing options, CMHC MLI Select construction offers a compelling alternative. At $200,000 per unit, this method delivers units that are 40% more energy-efficient than standard code requirements. The added benefit? Property owners can access up to 95% financing with just a 5% down payment, along with 50‑year amortization options - making it an attractive choice for long-term financial planning.

Construction Timelines and Assembly Installation

The timeline for fire‑rated construction hinges heavily on the installation of fire‑rated assemblies. Poorly managed projects can stretch from an expected 8 months to over 18 months due to coordination issues, permit delays, and inspection scheduling conflicts.

The construction process requires a carefully sequenced approach. For example:

- Wall assemblies must be completed before electrical and plumbing rough‑ins.

- Floor installations need to align with HVAC work.

- Ceilings can only be installed after final structural inspections.

Any disruption in these sequences can trigger delays across the entire project. Additionally, regulatory inspections are a major factor. Each fire‑rated assembly must pass specific checkpoints, and a failed inspection could stall progress while corrections and re‑inspections take place.

An integrated construction approach - where all trades operate under a single management system - can significantly reduce these delays. In some cases, this method has enabled projects to achieve completion in as little as 6 months, offering both speed and efficiency.

Fixed‑Price Contracts and Timeline Guarantees

While cost‑plus contracts often lead to 30–60% budget overruns, fixed‑price contracts provide a more secure alternative. By locking in costs before construction begins, these contracts eliminate financial uncertainty and help keep projects on track.

Beyond cost control, fixed‑price contracts often include timeline guarantees with financial penalties for delays. For example, a $1,000‑per‑day penalty for late completion ensures stricter adherence to schedules. This is a critical safeguard for property owners, as delays can result in significant losses - roughly $8,800 per month in missed rental income for a fourplex.

Additionally, streamlined, single-management systems help cut down on inefficiencies, which can save an average of $47,000 per project. By minimising coordination issues, change orders, and scope disputes, these systems keep both costs and timelines under control.

The biggest advantage of a guaranteed schedule? Predictable cash flow. With timelines firmly in place, property owners can confidently manage financing, market their units, and plan for rental income without worrying about unexpected delays.

Conclusion: Building Safe, Code-Compliant Properties That Pass Inspection

Constructing fire-rated assemblies for small multi-unit properties isn’t just about meeting code requirements - it’s about protecting lives, safeguarding investments, and ensuring the success of your project. Choosing the right construction approach plays a key role in overcoming these challenges.

The numbers clearly show the importance of a well-coordinated strategy. Successful projects hinge on thorough planning, precise execution, and clear accountability. On the other hand, fragmented methods can lead to delays, which may quickly chip away at your return on investment.

A systematic construction approach minimizes these risks. When design, engineering, and construction teams operate as a unified unit, fire-rated assemblies are built correctly the first time. Fixed-price contracts and guaranteed timelines provide the predictability property owners need.

By combining tested fire-rated assembly options with streamlined project management, you achieve both safety and efficiency. For property owners in Nova Scotia, the choice is clear: stick with disjointed methods that invite coordination issues and budget overruns, or opt for an integrated construction approach that ensures predictable costs, guaranteed timelines, and code-compliant results from the start. The safety of your tenants and the success of your investment depend on getting it right the first time.

The best multi-unit projects balance proper fire-rated construction with smart financial planning. Whether you're working with a budget of $160,000 per unit to maximize ROI or investing $200,000 per unit to leverage CMHC MLI Select financing benefits, integrating design, engineering, and construction from the beginning ensures predictable costs, reliable timelines, and first-time code compliance.

FAQs

What are the main reasons fire-rated assemblies fail inspections, and how can these issues be prevented?

The top reasons fire-rated assemblies fail inspections are improper installation and the use of incorrect materials. These problems usually arise when builders don’t strictly follow the standards set by fire-rated systems, such as UL or ASTM guidelines.

To avoid these pitfalls, always use materials that are explicitly approved for fire-rated applications and stick to the manufacturer’s installation instructions down to the smallest detail. This includes tasks like sealing joints properly, using the correct fasteners, and ensuring all components are compatible. Taking the time to plan thoroughly and train your team can help prevent costly errors and keep your project on track.

What are the cost and financing implications of choosing standard versus energy-efficient fire-rated assemblies for a small multi-unit building project?

The decision between standard and energy-efficient fire-rated assemblies can have a big impact on both your initial budget and long-term expenses. Energy-efficient options often come with a higher upfront price tag due to the use of advanced materials and technologies. However, they can lead to lower operating costs by improving insulation and cutting down on energy use, making them a smart choice over time.

On the financial side, energy-efficient assemblies may qualify for government incentives or green building programs, which could help offset those higher initial costs. Plus, they can boost your property’s value, making it more appealing to lenders and potential tenants. Striking the right balance between your current budget and the long-term advantages is crucial when deciding what’s best for your project.

What are the advantages of using an integrated design-build approach for fire-rated assemblies in small multi-unit buildings?

An integrated design-build approach can be a game-changer when constructing fire-rated assemblies for small multi-unit buildings. By consolidating both design and construction responsibilities under one accountable entity, this method minimizes miscommunication, speeds up timelines, and ensures projects align with Nova Scotia's building codes.

Traditional construction methods often involve juggling multiple contracts and dealing with fragmented responsibilities, which can lead to inefficiencies. In contrast, the design-build approach simplifies the process. Property owners benefit from fewer delays, more precise cost estimates, and a streamlined delivery system that prioritizes safety standards while reducing the risk of expensive rework.