Air Barriers and Vapour Control in Maritime Climates: Avoiding Condensation Failures

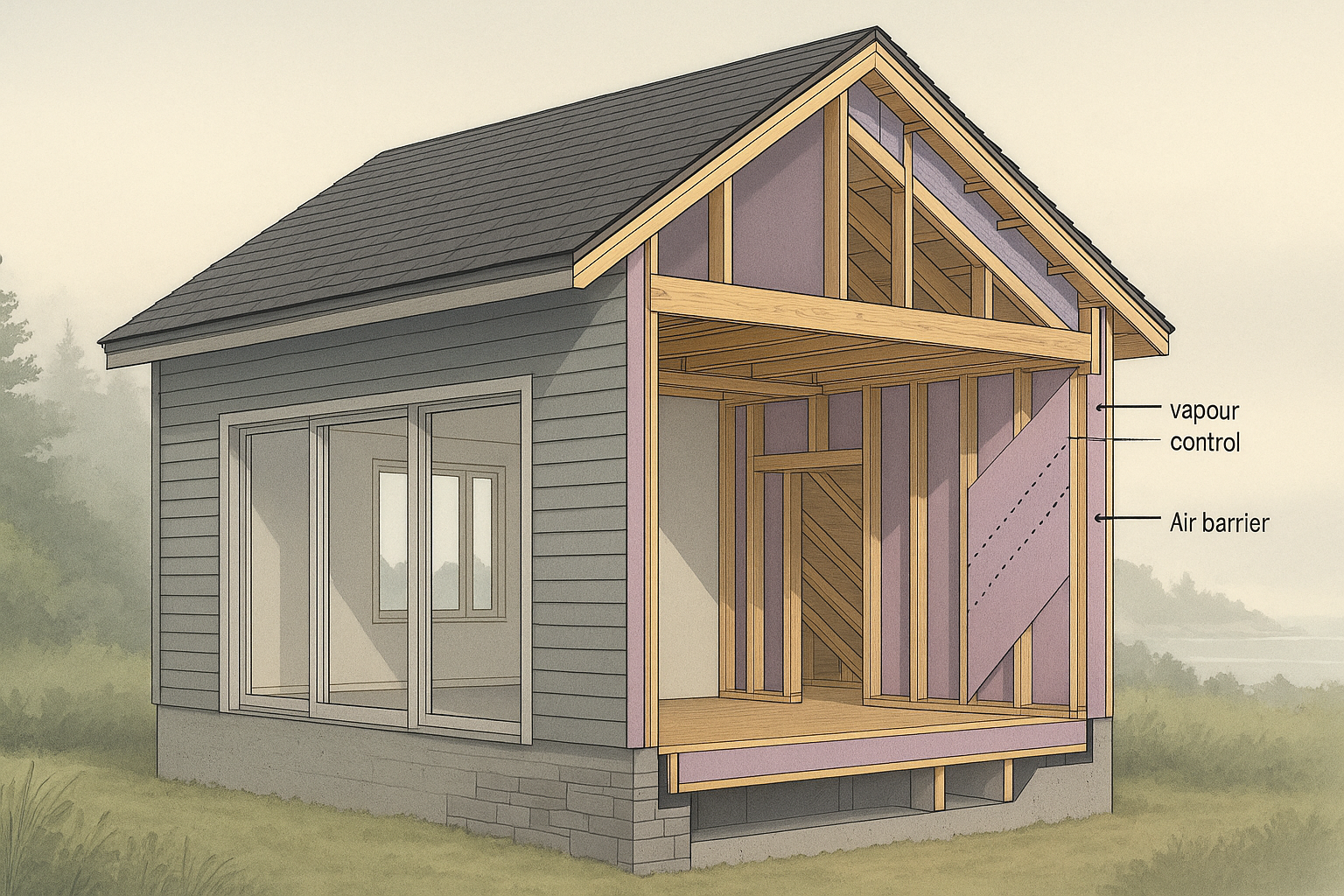

In Nova Scotia's humid, coastal climate, condensation inside walls can cause mould, structural damage, and costly repairs. To prevent these issues, buildings need air barriers to block humid air and vapour control systems to manage moisture movement. However, improper installation or using unsuitable materials can lead to failures, especially in multi-unit rental properties where moisture loads are higher.

Key takeaways:

- Air barriers block air and water infiltration, reducing condensation risks.

- Vapour control systems manage moisture diffusion, preventing trapped water.

- Proper installation and testing (e.g., blower door tests) are critical to avoid gaps.

- Smart membranes and ventilation systems (like HRVs) can handle Nova Scotia's temperature swings and high humidity.

- Integrated construction approaches reduce errors and improve long-term durability.

Air Barriers vs Vapor Barriers | You NEED To Know The Difference

How Maritime Climate Affects Building Envelopes

Nova Scotia's coastal climate presents a unique set of challenges for building envelopes, particularly when it comes to managing moisture. The combination of consistently high humidity and fluctuating temperatures creates an environment where moisture constantly moves through building materials, impacting their durability over time. To tackle this, construction methods need to be carefully adapted. Every decision, from the materials used to the finer details of installation, must account for the specific ways moisture behaves in this climate.

Temperature Changes and Dew Point Risks

In maritime regions, temperature swings are a regular occurrence. When warm, humid air comes into contact with a cooler surface, it can reach the dew point, leading to condensation. This is especially problematic within wall assemblies, where moisture naturally moves from warmer, more humid areas to cooler, drier ones[1][2]. This constant interaction underscores the importance of designing building systems that can handle such moisture migration effectively.

Why Standard Building Methods May Fall Short

Traditional building practices often assume conditions typical of continental climates, where seasonal patterns are more predictable. However, maritime environments are far less predictable, with humidity and temperature fluctuating more dynamically. Conventional construction methods, which often rely on fragmented systems for air barriers, insulation, and vapour control, can leave gaps in moisture management. These gaps can lead to serious issues in coastal settings. To address these complexities, a more integrated and coordinated approach is crucial - one that considers the unique demands of coastal conditions from the outset.

Air Barriers: Key Features for Coastal Durability

Air barriers are essential for protecting buildings in Nova Scotia's challenging coastal climate. Unlike vapour control layers, which manage moisture movement, air barriers are designed to block both air and bulk water from entering the building envelope. This is particularly important in areas like Halifax, with 121 foggy days annually, and Yarmouth, which experiences 191 foggy days per year. Choosing durable materials is crucial for ensuring long-term building performance in such conditions[4].

Nova Scotia's climate adds another layer of complexity, with extreme temperature swings ranging from -41.1°C in winter to 38.3°C in summer[3][4]. Buildings must also endure frequent nor’easters and occasional hurricanes[4][5]. Unfortunately, traditional construction methods often fail to provide the continuous protection needed to withstand the relentless moisture and wind typical of coastal environments.

Choosing the Right Air Barrier Materials

For maritime climates, the ideal air barrier materials must strike a balance between water resistance and vapour permeability. These materials need to block liquid water and air infiltration while allowing water vapour to escape from wall cavities. Without this breathability, trapped moisture can lead to condensation and damage within wall assemblies.

Self-adhered membranes are particularly effective in coastal settings. These materials feature exposed adhesive that allows for single-applicator installation without the need for primers. Additionally, nail sealability ensures that fastener penetrations are automatically sealed, reducing the risk of moisture intrusion. This is especially important in areas exposed to wind-driven rain. UV resistance is another critical feature, as it helps maintain the material's performance during prolonged exposure to coastal sunlight and salt air.

A good example is the 3M™ Air Barrier with Permeable Backing 3015VP, which combines these features with repositionable adhesives and a lightweight design. This allows for greater installation precision and ease of use in demanding conditions[3].

Installation Continuity and Common Errors

Selecting the right material is only part of the equation - proper installation is equally critical. Continuity during installation is essential, as even small gaps, tears, or poor seals can allow air and moisture to infiltrate the building envelope. In coastal environments, these breaches can lead to significant issues, especially with wind-driven moisture.

Primer-less application systems simplify the process, reducing the number of steps and potential failure points. Materials with repositionable adhesives allow for quick adjustments during installation without weakening the adhesive bond, which is especially useful around complex areas like window and door openings.

To further reduce errors, using integrated systems ensures compatibility across all components. For instance, systems like Pro Clima's INTELLO Plus, combined with accessories like TESCON VANA tape and ROFLEX gaskets, provide airtight seals around penetrations. This approach eliminates uncertainty about material compatibility and enhances overall reliability.

Testing and Verification for Air Tightness

Once installation is complete, verifying the system's integrity is crucial. Blower door testing is an effective way to measure actual air leakage, going beyond visual checks to ensure the system is functioning as intended. This testing not only confirms the quality of the installation but also helps prevent condensation issues that are common in Nova Scotia's maritime climate.

Conducting interim testing during construction allows crews to identify and fix problems early, while access to critical areas is still possible. Testing before interior finishes are installed avoids costly demolition and is particularly valuable in multi-unit projects.

For coastal construction, aiming for air leakage rates of 1.5 air changes per hour at 50 pascals (ACH50) or better provides a safety buffer against harsh conditions. Additionally, maintaining detailed documentation protocols that track leakage locations, repair methods, and retest results creates a valuable knowledge base. This systematic approach helps construction teams refine their methods for coastal environments, ensuring long-term performance and reliability through well-coordinated building envelope systems.

Vapour Control Systems: Managing Moisture and Preventing Condensation

In coastal areas like Nova Scotia, managing moisture is critical for maintaining the durability of buildings. This is where vapour control systems come into play, working alongside air barriers to regulate moisture diffusion through building materials. In the region's maritime climate, warm and humid indoor air tends to move toward the colder exteriors during winter. This can lead to condensation within wall cavities, causing issues like mould growth, damaged insulation, and even structural problems.

Vapour Barriers vs. Vapour Control Layers

Vapour barriers are designed to block moisture movement completely. Common examples include 6‑mil polyethylene sheeting and foil‑faced insulation, which have very low vapour permeance ratings - typically less than 0.1 perms. These materials are effective at stopping moisture but can create issues in climates like Nova Scotia's. If moisture does get trapped inside the wall - whether from air leaks or residual construction dampness - these impermeable barriers can prevent it from escaping, potentially leading to more severe damage.

On the other hand, vapour control layers take a more balanced approach. These materials slow down moisture movement without completely stopping it, with permeance ratings generally ranging from 0.1 to 1.0 perms. This allows wall assemblies to dry out if they become damp while still reducing moisture flow during the heating season. For example, kraft-faced fibreglass insulation, with a permeance of around 0.4 perms, provides effective moisture control while maintaining some drying capability. This approach is particularly useful in coastal areas where moisture can come from multiple sources.

Where to Place Vapour Control Layers

The placement of vapour control layers depends on understanding how moisture moves in your specific climate. In Nova Scotia, where winters dominate, the main concern is moisture travelling from warm indoor spaces to colder outdoor areas.

Traditionally, vapour control layers are installed on the warm side of the insulation, between the interior finish (like drywall) and the insulation itself. This ensures that moisture is intercepted before it can penetrate deep into the wall assembly, where condensation is most likely to occur.

It's equally important to consider the wall's ability to dry out. When the vapour control layer is placed on the interior, the materials on the exterior - like sheathing and cladding - should allow moisture to escape outward. For instance, OSB sheathing, with a permeance of 2–3 perms, is a better choice than exterior-grade plywood, which has a lower permeance. A good rule of thumb is to ensure that the exterior materials are at least five times more permeable than the interior vapour control layer. If you're using a 0.4-perm kraft facing on the inside, the exterior materials should have a combined permeance of at least 2.0 perms.

In advanced designs, vapour control layers can sometimes be placed on the exterior side of the insulation, especially in walls with significant exterior insulation. This requires careful planning to ensure the wall's interior remains above the dew point, but it can offer excellent drying potential toward the interior.

Smart Permeability Systems for Maritime Climates

For a more dynamic solution, smart permeability membranes are becoming increasingly popular, especially in maritime climates like Nova Scotia's. These advanced membranes adjust their permeance based on humidity levels, offering better moisture management throughout the seasons. When humidity is low, they tighten their control, and when it rises, they allow for greater drying potential.

A great example is Pro Clima's INTELLO Plus, which changes its permeance based on conditions. In winter, it operates at around 0.17 perms, but as relative humidity rises above 45%, it allows for faster drying. These membranes are part of a system that includes compatible sealing products like TESCON VANA tape for seams and ROFLEX gaskets for airtight seals around penetrations.

Mechanical ventilation systems can also complement vapour control strategies. Panasonic's WhisperSense fans, for instance, automatically increase ventilation when indoor humidity exceeds a set threshold, reducing the burden on vapour control systems. This is particularly useful in multi-unit rental properties, where activities like cooking, showering, and laundry can cause temporary humidity spikes. Smart permeability materials help manage these fluctuations while maintaining protection under normal conditions.

Ultimately, the success of any vapour control system lies in its integration into a broader building envelope strategy. When combined with proper air sealing, thermal bridging control, and mechanical ventilation, these systems provide a robust defence against the challenges of Nova Scotia's damp maritime climate.

sbb-itb-16b8a48

Common Condensation Failures in Multi-Unit Rental Properties

Multi-unit rental properties in Nova Scotia often face condensation issues, which can lead to costly repairs and discomfort for tenants. The combination of high coastal humidity and daily household activities creates an environment where condensation problems can quickly escalate if not properly addressed. Understanding the common causes of these failures can help property owners tackle potential issues before they worsen. Below are some of the most frequent condensation-related problems and their effects on building durability.

Interstitial Condensation and Wall Cavity Damage

Interstitial condensation happens when warm, moist air seeps into wall cavities and meets cold surfaces, causing moisture to accumulate in hidden areas. This trapped moisture can lead to significant damage that often goes unnoticed until it’s too late.

In multi-unit buildings, the problem is magnified due to the moisture produced by multiple households. For example, a single four-person household generates enough moisture annually to fill approximately 280 buckets through activities like cooking, bathing, and laundry [7]. Multiply this by several units, and the moisture load becomes overwhelming.

One common cause of interstitial condensation is poorly installed vapour barriers. Tears, unsealed seams, or incomplete coverage around penetrations allow moisture-laden air to infiltrate wall cavities. Once inside, this moisture condenses on cold surfaces like sheathing or framing, reducing insulation efficiency, overworking heating systems, and creating conditions for mould growth. Mould can develop within just 24 to 48 hours on damp materials such as wood framing or paper-faced drywall.

Over time, repeated cycles of wetting and drying weaken building materials, compromising the structure’s integrity. These failures undermine the overall effectiveness of the building envelope, leading to long-term durability issues.

Thermal Bridging and Surface Condensation

Thermal bridging occurs when heat escapes through highly conductive materials like steel studs, concrete, or continuous wood framing, bypassing insulation and creating cold spots. These cold areas are prone to condensation when they come into contact with warm, humid indoor air. Studies indicate that thermal bridging can account for up to 30% of heat loss in a home [6][10]. The resulting water droplets create ideal conditions for mould growth and structural degradation.

Windows and doors are particularly vulnerable to thermal bridging. For instance, traditional installation methods using poorly insulated wood bucks around window openings often create pathways for heat loss, leading to condensation and mould growth [8]. Other problem areas include balcony connections and structural penetrations. A concrete balcony slab that extends through the building envelope, for example, can create cold spots near sliding doors, increasing condensation risks.

In modern, airtight buildings, indoor humidity levels during winter can reach 30% to 40%. This further increases the likelihood of condensation forming on cold surfaces, especially around penetrations where the dew point is reached [9]. Beyond energy inefficiency, these issues can result in damage requiring extensive repairs.

While thermal bridging creates localized cold spots, poor ventilation can make condensation problems even worse.

Ventilation Problems and Humidity Buildup

Inadequate ventilation is another major contributor to condensation issues in multi-unit properties. When mechanical ventilation systems fail to remove moisture effectively, indoor humidity levels rise, exacerbating both interstitial and surface condensation problems.

Many multi-unit buildings rely on undersized or poorly designed ventilation systems. Each unit needs sufficient exhaust capacity in moisture-heavy areas like kitchens, bathrooms, and laundry rooms, along with a balanced supply of fresh air. When these systems are inadequate, moisture from everyday activities accumulates faster than it can be expelled.

Tenant behaviour can also play a role. Actions like turning off exhaust fans or blocking vents can worsen humidity levels. Maintenance issues, such as clogged or noisy fans, further reduce system performance. In buildings where ventilation systems are shared between units, a failure in one area can affect neighbouring units.

The impact of poor ventilation is not limited to Nova Scotia. In Australia, one in three buildings has experienced mould growth, leading to health risks and costly remediation [11]. As homes become more airtight and better insulated, thermal bridges and condensation risks become even more pronounced, highlighting the importance of proper ventilation and design [7][9].

Complete Strategies for Preventing Condensation Failures

To prevent condensation failures, it’s crucial to combine air barriers, vapour control, insulation, and ventilation throughout the design and construction process. These elements work together: a well-planned air barrier reduces the burden on ventilation systems, while proper insulation helps manage temperature differences that lead to condensation. When these components are aligned, the result is a building that’s not only energy-efficient but also durable enough to handle Nova Scotia’s challenging coastal climate. This approach forms the backbone for addressing thermal, ventilation, and HVAC performance.

Achieving Thermal Continuity and Avoiding Thermal Bridges

Maintaining thermal continuity - consistent insulation across the building envelope - is essential. In maritime climates, even small thermal bridges can create cold spots that encourage condensation. A practical solution is to use continuous exterior insulation that wraps around the entire structure. By placing insulation on the exterior side of the framing, thermal bridging is minimized, and structural components stay warmer.

Upgrading to thermally broken window and door systems is another effective step. Installing windows within the insulation layer, using thermally broken mounts, ensures a warmer perimeter around openings. Similarly, balcony and foundation connections demand careful attention. For instance, thermal break systems at balcony connections or extending insulation from the foundation through the wall assembly can create a seamless thermal envelope, significantly reducing condensation risks.

Ventilation Design for Managing Humidity

Once insulation strategies are in place, the next step is optimizing ventilation to directly address humidity. Mechanical ventilation plays a critical role in controlling indoor moisture levels and preventing condensation. For multi-unit buildings, ventilation systems should be designed to expel moisture while introducing fresh air, adhering to local building codes. Spaces like bathrooms and kitchens - where moisture levels are higher - require exhaust systems tailored to their specific moisture loads.

In coastal regions, heat recovery ventilators (HRVs) and energy recovery ventilators (ERVs) are often used. HRVs recover heat from outgoing air to pre-warm incoming air, reducing energy consumption while maintaining proper airflow. ERVs go a step further by also transferring moisture between air streams, helping to balance indoor humidity levels throughout the year. Additionally, it’s essential to seal ductwork that penetrates the air barrier to maintain the integrity of the building envelope. Together with insulation and air barriers, effective ventilation completes the moisture management system.

Integrating Heat Pumps and Coastal-Specific Solutions

Modern HVAC systems, particularly cold-climate heat pumps, enhance building performance when paired with an efficient building envelope. These heat pumps provide both heating and cooling while also managing indoor humidity levels. Ductless heat pump systems are especially beneficial for multi-unit buildings, as they eliminate ductwork, which is often a source of air leaks and condensation. These systems also offer precise control over temperature and humidity.

To fully integrate heat pumps with the building envelope, careful planning is required. For instance, refrigerant line penetrations must be sealed, and mounting methods should minimize thermal bridging. Smart controls can further optimize performance by coordinating heat pumps, ventilation, and envelope systems to maintain ideal indoor conditions while conserving energy.

The success of these integrated systems hinges on close collaboration among design, engineering, and construction teams. When all stakeholders work together from the start, the interaction between building systems is optimized, reducing performance gaps and ensuring a well-functioning, condensation-resistant structure.

Construction Execution and Quality Assurance

When it comes to designing integrated air barriers and vapour control systems, precise execution during construction is what truly brings these designs to life - especially in Nova Scotia’s tough maritime climate. In regions where moisture issues can crop up quickly, proper installation and thorough verification are essential for ensuring buildings stand the test of time.

Installation Sequencing and Trade Coordination

Getting the sequence right and coordinating trades is key to maintaining the integrity of air barriers and vapour control systems. Every trade involved must fully understand how their work impacts the building envelope. A small oversight here can compromise the entire system.

Start by inspecting the framing to ensure proper alignment and secure connections. Gaps in framing can lead to thermal bridges and condensation - problems you definitely want to avoid. Installing air barriers is all about precision. Membranes or coatings should be applied only under suitable weather conditions. In coastal Nova Scotia, timing is everything. Plan installations during favourable weather windows to make sure every seam, penetration, and transition is sealed without delay.

Rough-ins, like electrical boxes, plumbing, and HVAC connections, often disrupt air barrier continuity. These should be sealed immediately during installation while access is still easy. Insulation work also needs careful coordination with air barrier installation. Whether it’s cutting batt insulation precisely around penetrations or applying spray foam at the correct thickness to prevent shrinkage, attention to detail here makes all the difference. These steps lay the groundwork for effective on-site testing and verification later.

On-Site Testing and Verification Protocols

Blower door tests should be conducted at multiple stages of construction to check air barrier performance. The first test is best done right after the air barrier is installed but before insulation goes in. Using infrared cameras during these tests can help pinpoint leaks, while moisture monitoring ensures wood framing stays below 19% moisture content - a critical threshold for avoiding long-term issues.

After insulation is installed, thermal imaging can uncover hidden thermal bridges or gaps that could lead to condensation during colder months. To stay ahead of potential problems, maintain detailed quality checklists. Catching and fixing sealing errors early not only saves money but also prevents disruptions down the road.

While rigorous testing is an important part of the process, consolidating responsibility under single-source builders can make quality assurance even more streamlined.

Ensuring Accountability with Single-Source Builders

Traditional construction often involves multiple contractors, which can lead to gaps in accountability - especially when different teams handle various parts of the building envelope. Integrated building envelope solutions take a different approach, significantly reducing coordination issues. For example, systems from Sto Corp. combine air and vapour barriers into cohesive components, minimizing interfaces and potential failure points [12]. These systems simplify labour, reduce risks, and cut down on the complexity that comes with juggling multiple separate components [12].

Single-source accountability means one company takes responsibility for all envelope-related work. This eliminates the blame game when problems arise and gives property owners a single point of contact for resolving issues. By avoiding the disputes and delays common in fragmented delivery models, this approach keeps coordination costs low and ensures smoother project execution.

With all teams aligned on the same performance goals, quality assurance protocols become far more effective. Testing is integrated into every critical stage of construction, rather than being left until the end when fixes are more expensive and disruptive.

Take Helio Urban Development, for example. By integrating design, engineering, and construction teams from the get-go, they minimize coordination challenges and deliver fixed-price, on-time projects. This kind of approach is crucial for achieving durability and energy efficiency in Nova Scotia’s demanding maritime conditions.

Conclusion: Building for Durability and Energy Efficiency in Nova Scotia

Constructing multi-unit rental properties in Nova Scotia's maritime climate requires a tailored approach. The region's high humidity, fluctuating temperatures, and coastal moisture pose challenges that standard construction methods often fail to address effectively.

The solution lies in using integrated air barrier and vapour control systems that function as a unified whole. This involves choosing materials specifically designed for maritime environments, following precise installation procedures, and maintaining strict quality checks throughout the process. These measures not only protect the building structure but also provide clear financial and operational benefits.

Investing in these systems pays off significantly. By preventing condensation-related damage, property owners can save thousands in repair costs while ensuring steady rental income. Energy-efficient building envelopes help reduce heating expenses - an important factor in Nova Scotia's climate, where tenants often bear utility costs. Additionally, properties built with robust moisture management retain their value better and attract tenants seeking comfortable, healthy living spaces.

As discussed earlier, fragmented construction models often lead to moisture control issues. When multiple contractors handle different parts of the building envelope, coordination gaps arise, resulting in problems that may only become visible months or years later. Addressing these issues post-construction can be both costly and disruptive.

An integrated construction approach solves this problem by consolidating design, engineering, and construction expertise within a single team. Companies like Helio Urban Development exemplify this model, offering fixed-price contracts and guaranteed timelines while taking full accountability for the building envelope's performance.

By prioritizing maritime-specific construction methods and investing in proper air and vapour barriers from the outset, property owners can avoid expensive moisture problems down the road. This upfront commitment leads to lower operating costs, reduced maintenance needs, and stronger long-term rental returns.

While Nova Scotia's coastal climate will always present moisture-related challenges, the right combination of materials, meticulous installation, and unified construction practices makes these challenges manageable. This approach ensures durable, energy-efficient buildings that protect your investment and provide tenants with a comfortable, high-quality living experience.

FAQs

What is the difference between air barriers and vapour control systems in managing moisture in coastal climates?

Air barriers play a key role in blocking the movement of air and the moisture it brings along, which helps boost energy efficiency and maintain better indoor air quality. Vapour control systems, on the other hand, work to slow down the passage of water vapour through materials, reducing the risk of condensation and moisture-related damage.

In coastal regions like Nova Scotia, where humidity often runs high, both systems are crucial. Air barriers help cut down on drafts and prevent heat from escaping, while vapour control systems stop water vapour from condensing within walls - a situation that could lead to mould growth or structural problems. Together, these systems help keep buildings sturdy and comfortable, even in the demanding conditions of maritime climates.

What steps can property owners take to properly install air barriers and vapour control systems and avoid condensation issues in maritime climates?

To tackle condensation issues in humid, coastal areas like Nova Scotia, it’s crucial to grasp the roles of air barriers and vapour control systems. Air barriers are designed to block airflow and need to be continuous, sturdy, and impermeable. On the other hand, vapour barriers manage moisture movement and must be chosen carefully, taking into account the local climate and the specific design of the building.

Effective installation requires selecting materials that can withstand Nova Scotia’s maritime conditions. It’s equally important to ensure all components are sealed and integrated properly into the building envelope. Working with seasoned professionals who are well-versed in these systems can help sidestep expensive errors and promote long-term durability and energy efficiency.

Why is an integrated construction approach better for preventing moisture issues in Nova Scotia's coastal climate?

In Nova Scotia's coastal climate, an integrated construction approach proves far more effective because it ensures all elements of the building process work in harmony to combat moisture challenges. This method emphasizes choosing the right materials, applying tested design principles, and employing specialized construction techniques to prevent condensation and its associated problems.

By tackling moisture concerns as a whole, this strategy minimizes the likelihood of expensive errors while promoting durability and energy efficiency. This is especially crucial in the humid, maritime conditions that define Nova Scotia.