Advanced Framing vs Conventional: Material Savings and Thermal Bridges in NS

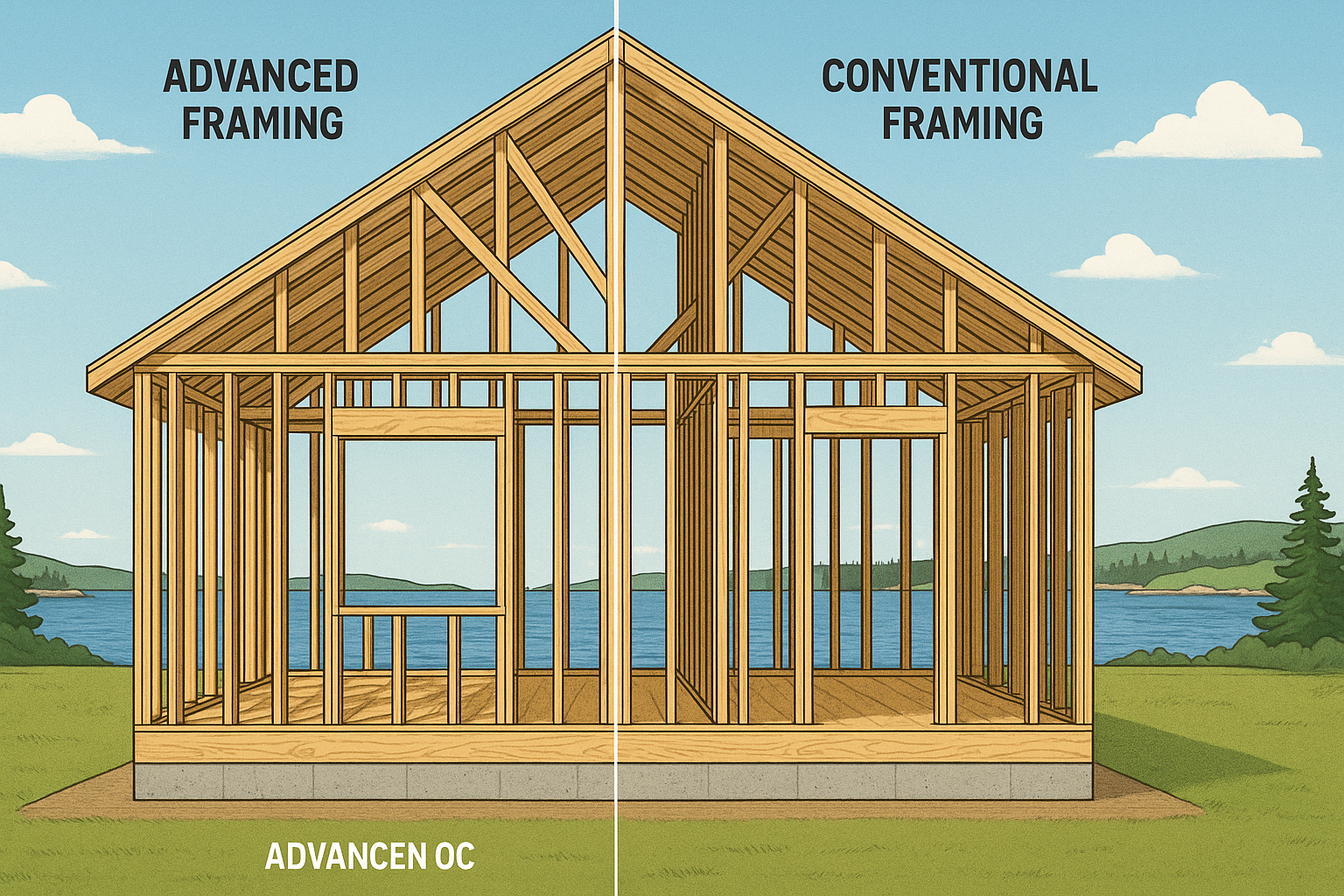

Advanced framing and conventional framing are two common methods for constructing wood-framed buildings in Nova Scotia. While conventional framing is widely used due to its simplicity, advanced framing offers lower material costs, reduced thermal bridging, and improved energy efficiency - key factors for property owners in Nova Scotia's challenging climate. Here's a quick breakdown:

-

Advanced Framing:

- Uses fewer materials (e.g., 24-inch stud spacing, single top plates, two-stud corners).

- Reduces wood waste and allows for more insulation, improving energy performance.

- Cuts lumber costs by up to $1,000 for a 2,400 sq. ft. house.

- Lowers labour costs by 3% to 5%.

- Reduces thermal bridging by decreasing the "Framing Factor" from 25% to 15%.

-

Conventional Framing:

- Relies on 16-inch stud spacing, double top plates, and three-stud corners.

- Consumes more lumber, increasing costs and waste.

- Higher thermal bridging results in lower energy efficiency.

- Familiar to most builders but less efficient for Nova Scotia's energy needs.

Quick Comparison

| Feature | Advanced Framing | Conventional Framing |

|---|---|---|

| Stud Spacing | 24 inches | 16 inches |

| Top Plates | Single | Double |

| Corners | Two-stud | Three-stud |

| Material Savings | Up to $1,000 (2,400 sq. ft.) | Higher material use, no savings |

| Labour Costs | 3%-5% lower | Standard |

| Thermal Bridging | Lower (15% Framing Factor) | Higher (25% Framing Factor) |

| Energy Efficiency | Higher | Lower |

For Nova Scotia's cold winters and high heating costs, advanced framing provides better long-term energy savings and lower upfront material use. However, proper execution and experienced builders are essential for meeting structural and code requirements.

Traditional vs Advanced Framing - Details

Advanced Framing: Less Material, Better Performance

Advanced framing redefines wood construction by focusing on efficiency. Instead of overusing lumber, this method strategically places structural components where they’re most needed. The result? Less waste, lower costs, and better energy performance - advantages that benefit every property owner.

Advanced Framing Methods

Advanced framing is all about designing structures to efficiently transfer vertical loads to the foundation while cutting back on unnecessary materials [1]. It’s not about skimping; it’s about smart resource use.

One key feature is 24-inch stud spacing, which replaces the traditional 16-inch spacing. This wider spacing reduces the number of studs without compromising structural integrity. Another technique involves using single top plates instead of the conventional double top plates. When framing members are properly aligned, a single plate distributes loads effectively, especially when floor systems align with the wall framing below.

Corners also get an upgrade. Two-stud corners replace the typical three- or four-stud assemblies. This change minimizes thermal bridging, allows for more insulation, and cuts down on lumber use while maintaining strength. Similarly, optimized headers ensure materials are used only where necessary. In non-load-bearing walls, headers can often be eliminated altogether. For load-bearing walls, headers are sized specifically for the loads they need to support rather than defaulting to oversized lumber.

Advanced Framing Benefits

The financial benefits of advanced framing are clear. For a 1,200-square-foot house, material savings can reach up to $500, and for a 2,400-square-foot house, they can climb to $1,000 [3]. For multi-unit buildings, these savings multiply across each unit, boosting returns for property owners.

Labour costs also drop, with potential savings of 3% to 5% [3]. Fewer framing components mean less cutting, handling, and assembly time, leading to shorter construction timelines and reduced labour expenses.

Environmental benefits are just as compelling. Advanced framing can lower the "Framing Factor" - the portion of a wall occupied by wood - from 25% in conventional framing to 15% [1]. This means less wood waste and more efficient use of forest resources. Additionally, reduced thermal bridging creates more room for insulation, which is especially valuable in Nova Scotia, where heating costs are a major concern.

Meeting Nova Scotia Building Codes

While advanced framing is efficient, it still needs to meet Nova Scotia’s building codes, including requirements for wind loads and other regional challenges unique to the maritime climate.

To ensure compliance, it’s essential to work with builders experienced in advanced framing. Proper engineering ensures that wider stud spacing and fewer framing members still meet structural demands for local weather conditions.

Building officials in Nova Scotia are generally familiar with these techniques. Clear documentation and precise engineering calculations can help streamline permit approvals and inspections.

For multi-unit buildings, advanced framing offers even more benefits. The repetitive nature of these projects allows for standardized, optimized designs that reduce material costs and simplify construction while maintaining the structural integrity needed for long-term rental properties. Next, we’ll explore how these benefits compare to the limitations of conventional framing methods.

Conventional Framing: Standard Methods and Limitations

Even though advanced framing techniques offer better efficiency, conventional framing remains the go-to choice for many builders. Its widespread use stems from its simplicity and long-standing familiarity. But this traditional approach has its downsides, particularly for property owners in Nova Scotia, where energy efficiency is critical due to the region's challenging climate. These drawbacks often translate into higher material and energy costs.

Standard Framing Methods

Conventional framing relies on 16-inch stud spacing for vertical supports. This method uses double top plates, which help distribute loads but also increase lumber consumption. For corners, builders use three-stud assemblies to ensure structural strength, though this adds to material use and contributes to thermal bridging. Additional materials, such as double headers, jack studs, and corner cripple studs, further increase lumber requirements. Most walls are typically built with 2x4s, resulting in shallow wall cavities that limit the amount of insulation that can be installed.

Material Waste and Energy Loss Problems

One major drawback of conventional framing is its high wood occupancy, known as the 25% Framing Factor, which reduces the area available for insulation. Each piece of lumber acts as a thermal bridge, allowing heat to escape and lowering the overall insulation efficiency. The use of numerous structural components and connections also increases the chances of air leakage. These inefficiencies stand in stark contrast to the improved thermal performance achieved with advanced framing techniques [1].

Why Builders Still Use Conventional Framing

Despite its limitations, conventional framing persists because it's familiar and straightforward. Most carpentry crews are trained in these traditional methods, which minimizes errors and ensures a smooth construction process [4].

"Builders have generally been reluctant to implement advanced framing techniques in the past. Reasons for opposition include the potential for higher up-front labor costs for carpentry crews to alter standard construction practices, concern about suitability for high wind and seismic-prone areas, and resistance by some contractors and code officials."

Other barriers include the need for ongoing training for framing contractors and resistance from some contractors and building officials who prefer methods that already meet inspection standards [5]. Additionally, the perception of higher up-front labour costs often discourages builders from switching to advanced methods [4].

These inefficiencies are particularly impactful for multi-unit rental properties, where they can lead to higher long-term costs and poorer energy performance. As the next section will explore, the material inefficiencies inherent in conventional framing significantly affect overall project expenses and energy outcomes.

Material Savings: Advanced vs Conventional Framing Costs

Advanced framing takes a smarter approach to lumber use by cutting out unnecessary structural elements and avoiding the traditional over-framing method. This not only reduces the amount of material needed but also generates less waste, making it a more efficient and eco-friendly option for wood-frame construction. These efficiencies translate into lower overall construction costs.

Material Usage Comparison

With advanced framing, the structural support is achieved using fewer materials, thanks to designs that maximize efficiency without sacrificing strength or safety.

Waste Reduction and Cost Savings

By streamlining construction methods, advanced framing reduces the need for extra lumber, labour, and hardware. This approach helps lower costs while maintaining high-quality construction standards. As noted by an industry expert:

"Advanced framing reduces the amount of lumber used in construction in a practical way that is also environmentally beneficial." - Insulation Institute [4]

Environmental Impact Differences

Cutting back on lumber use has a direct impact on reducing the environmental footprint of construction projects. Given that nearly 50% of all wood consumed in North America is used for building construction [1], adopting methods like advanced framing becomes even more critical. By producing less waste and improving efficiency, this technique also helps lower carbon emissions over the life of the building. Experts emphasize this point:

"While wood is a renewable resource, wood-frame construction that utilizes advanced framing techniques delivers even greater environmental dividends by optimizing material usage and reducing construction waste." - Insulation Institute [4]

For property owners in Nova Scotia planning multi-unit rental projects, advanced framing isn't just a cost-effective option - it's also a step toward more sustainable construction practices.

sbb-itb-16b8a48

Thermal Bridging and Energy Performance in Nova Scotia

This section delves into how thermal bridging impacts energy performance, a key consideration for multi-unit rental properties in Nova Scotia.

Given Nova Scotia's cold winters, managing heating costs is a priority. For multi-unit rental buildings, designing an efficient building envelope to reduce heat loss is essential for maintaining long-term energy performance.

What Is Thermal Bridging?

Thermal bridging happens when materials with high thermal conductivity - like wood studs - create pathways for heat to escape from the interior to the exterior. In typical framing, these thermal bridges occur wherever structural elements, such as studs, headers, or plates, connect the inside and outside of a wall. When large portions of a wall are taken up by lumber, the overall insulation is compromised by these heat loss pathways. Minimizing these pathways is a crucial step in improving energy performance for buildings in Nova Scotia.

Energy Performance: Advanced vs Conventional

Advanced framing techniques reduce the framing factor from about 25% to 15%, cutting down thermal bridges and enabling the use of deeper wall cavities for additional insulation [1].

Optimum Value Engineering (OVE) takes it a step further by pairing studs with extra insulation, further minimizing thermal bridging [2]. This combined strategy significantly improves the wall's ability to retain heat during Nova Scotia's long winters.

Energy Savings and ROI for Property Owners

Reducing heat loss through better thermal performance not only lowers energy bills but also boosts the return on investment (ROI) for property owners. Adding continuous insulation - which covers the entire exterior, including the framing members - further prevents heat from escaping [6]. This results in a more consistent and efficient building envelope.

The benefits are clear: lower operating costs, improved indoor comfort, and stronger financial returns for property owners.

Integrated Construction: Advanced Framing with Fixed Pricing

Advanced framing offers clear benefits in terms of material efficiency and energy savings. But when paired with an integrated design-build approach, it becomes even more powerful. By addressing the common challenges of traditional construction, this method ensures predictable costs and timelines - making it especially appealing for multi-unit rental projects.

Fixed Pricing and Timeline Guarantees

One of the biggest headaches in conventional construction is the uncertainty around costs and timelines. Traditional methods, with their fragmented contracting, often lead to delays and unexpected expenses. This makes it harder to fully capitalize on the advantages of advanced framing.

Integrated construction teams solve this problem by combining design, engineering, and construction under one roof. This streamlined approach allows for fixed-price construction at $160,000 per unit, along with a guaranteed 6-month completion timeline - complete with penalties for delays. This not only locks in savings but also reduces the risks typically associated with traditional construction practices.

The cost predictability of integrated fixed pricing further enhances the savings from advanced framing. With accurate pricing baked into fixed contracts, property owners know exactly what they’re spending and when they can start earning. For instance, a typical fourplex generating $8,800 in monthly rental income becomes a much more reliable investment.

Avoiding Coordination Problems

Advanced framing techniques require a high level of coordination between trades to deliver their full benefits. For example, the wider spacing used in advanced framing simplifies tasks for all trades involved [4]. However, this advantage can vanish when multiple contractors, working independently, fail to align their efforts.

Integrated construction teams eliminate these coordination issues. By managing all trades in-house, they can sequence installations efficiently, maximizing the labour savings that advanced framing offers [4]. This ensures smoother project execution and avoids miscommunication or conflicts between contractors.

Another benefit of this approach is the reduction in construction waste, which translates to savings on dumpster and disposal costs [4]. Integrated teams can plan deliveries and installations with precision, cutting down on excess materials. This level of coordination also supports the proper installation of energy-efficient systems, reinforcing the advantages of advanced framing discussed earlier.

Higher ROI Through Better Construction

With better coordination in place, the financial benefits of advanced framing only grow. While material savings are a clear win, integrating advanced framing with fixed contracts unlocks even greater returns over time.

For example, advanced framing improves energy efficiency, with cavity insulation covering 85% of the wall area compared to 75% in traditional framing [1]. This leads to reduced operating costs for tenants, which can make a property more attractive to renters and justify higher rents. In turn, property owners benefit from increased rental income and higher property values.

Additionally, the energy efficiency of advanced framing can help property owners secure financing advantages. For those pursuing CMHC MLI Select financing, integrated builders ensure compliance with energy efficiency requirements. This opens doors to 95% financing with a 50-year amortization period, which can significantly improve cash flow - even when construction costs rise to $200,000 per unit.

Finally, integrated construction teams provide rigorous quality checks and comprehensive warranties. This not only protects the property owner’s investment but also ensures that the advanced framing system performs as expected throughout the building’s lifespan. With fixed pricing, guaranteed timelines, and long-term reliability, property owners can confidently maximize their returns.

Conclusion: Picking the Right Framing Method

Selecting the right framing method is crucial for maximizing returns and addressing Nova Scotia's climate challenges effectively.

Key Points for Property Owners

We've highlighted how choosing the right framing method can directly cut costs while improving energy performance. Advanced framing, in particular, stands out for its benefits in multi-unit rental properties. By enabling better cavity insulation, it lowers heating costs and enhances tenant comfort, leading to noticeable savings.

That said, these advantages depend heavily on precise execution. Traditional construction methods - often involving fragmented contracts and poor coordination among trades - can undermine the precision needed for advanced framing. This can result in issues like thermal bridging and inefficiencies in labour.

An integrated construction approach solves these problems. When all trades operate under one management system, the optimized layout and wider stud spacing that advanced framing requires can be implemented correctly. The result? Faster construction timelines and better energy performance, which ultimately contribute to stronger long-term profitability.

Making Smart Decisions for Long-Term Profits

Smart construction choices can lead to lower operating costs and higher rental income over time. A multi-unit property with improved energy efficiency not only reduces utility expenses for tenants but also has the potential to attract higher rents.

The fixed pricing and systematic delivery methods mentioned earlier position properties to adapt seamlessly to future regulatory changes and evolving tenant expectations.

For property owners navigating Nova Scotia's competitive rental market, opting for integrated advanced framing ensures predictable costs and superior performance. When executed properly, this approach offers a clear edge in both profitability and sustainability.

FAQs

How does advanced framing improve energy efficiency in Nova Scotia’s cold climate?

Advanced framing is a construction technique that boosts energy efficiency by cutting down on thermal bridging - the process where heat escapes through materials like wood studs. By reducing the number of studs and filling the gaps with extra insulation, this approach creates a more consistent thermal barrier. The result? Indoor spaces stay warmer during Nova Scotia’s chilly winters.

Beyond limiting heat loss, advanced framing also cuts down on material waste. This makes it a smart, eco-conscious option for property owners aiming to improve energy performance in their buildings while managing costs effectively.

What challenges might arise when using advanced framing techniques in construction projects?

Advanced framing comes with its share of challenges that are worth keeping in mind. First, the technique often requires workers with specialized expertise, which can lead to higher upfront labour costs. Another consideration is its performance in regions exposed to high winds or seismic activity - meticulous planning is necessary to maintain the structure's strength and safety in these conditions. Lastly, resistance from contractors and building code officials can be an obstacle, as some may lean towards conventional methods due to a lack of familiarity or comfort with the approach.

How does an integrated construction approach maximize the advantages of advanced framing for multi-unit rental properties?

An integrated construction approach streamlines the application of advanced framing techniques, ensuring they’re used effectively in multi-unit rental projects. By aligning design, materials, and construction under one unified team, this method helps cut down on waste, boosts energy efficiency, and maintains consistent quality throughout the entire building process.

In Nova Scotia’s climate, advanced framing plays a key role in reducing thermal bridging, which enhances insulation and lowers heating costs. When paired with an integrated process, property owners can enjoy notable material savings, more predictable construction timelines, and better financial returns on buildings ranging from 4 to 24 units.